Page 9 - AAA JULY - AUGUST 2015 Online Magazine

P. 9

FEATURE AVIATION TRENDS

officials have stated that they expect the 24 has a couple of unique aspects to its and pressurised cabin. Customers can

split between PC-24 orders to also have design. The first is the lack of winglets, also select the option to have passenger

the same ratio. Canada is another big which despite being demanded by the seats that can be removed or added

market for the type, with more than 100 marketing team was shot down by the in quick time. According to company

airplanes having been delivered. More engineers who felt that the efficiency gains officials, a number of configurations were

than 60 PC-12s have also found a home in would not offset the increased weight and researched before settling in on the final

Australia. The Royal Flying doctors, based fuel penalty. A substantial amount of work configuration. The PC-24 will have biggest

in Australia are the launch customer for has also been put into the design of the pressurised baggage compartment in its

the type, where the cargo door will prove a wing which provides for a stall speed of 81 class. The spacious and flexible cabin can

huge asset to its operations there knots at max landing weight. The single be configured in a high density 10 seat

Development testing of the PC24 is piece wing developed internally, carries configuration with a toilet if required.

well underway now, following the maiden 2700 kg of fuel and features double slotted

flight undertaken by Prototype P01 (call flaps. The double wheel landing gear on

sign HB-VXA), in May, this year. Follow- the PC-24 is the same as that used on the

on flights have seen P01 complete 50 PC-12, and uses the same low pressure

hours of flight and 30 landings (as of July tyres. Rough and short-field performance

7th). Four Pilatus test pilots have now is likely to be exceptional, with the ability

been qualified on the type for further to operate from unpaved runways that

developmental testing. There will be three have a minimum length of at least 2,690

PC-24 prototypes in total, and they will be feet (820 m). The two Williams FJ44-4A

used to fly a comprehensive 2,300 hour turbines, each produce a max take-off

test programme over the next two years. thrust of 3,400 lbf. Maximum payload

Less than half of the required 2,300 hours is 1,125 kg with 450 kg of fuel. Another

will be flown in Switzerland. Certification aspect is the cargo door which remains

and delivery of the first series-produced a Pilatus hall mark and the PC-24, will

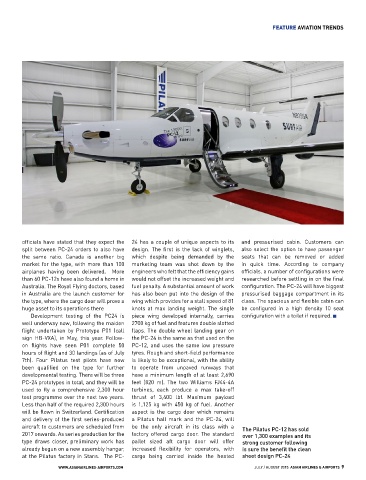

aircraft to customers are scheduled from be the only aircraft in its class with a The Pilatus PC-12 has sold

2017 onwards. As series production for the factory offered cargo door. The standard over 1,300 examples and its

type draws closer, preliminary work has pallet sized aft cargo door will offer strong customer following

already begun on a new assembly hangar, increased flexibility for operators, with is sure the benefit the clean

at the Pilatus factory in Stans. The PC- cargo being carried inside the heated sheet design PC-24

WWW.ASIANAIRLINES-AIRPORTS.COM JULY / AUGUST 2015 ASIAN AIRLINES & AIRPORTS 9