Page 30 - ADT MAY-JUNE 2022 Online Magazine

P. 30

is the norm, code is rewritten, modified and shared

all the time. Challenges are solved once, and the

best solution propagates quickly. Why would you

use a function with inferior results when a better

one exists? [ COLUMN ]

Let’s move engineering under the same paradigm.

Engineers should encode the design process

into algorithms and let the computer generate

the geometry. They should share, collaborate,

and create intellectual property that is indepen-

dent of a specific design. We call it Algorithmic

Engineering and with Hyperganic Core, we cre-

ated a platform for that process. One key enabler

for this technology is Additive Manufacturing

(AM). AM allows us to create objects with less

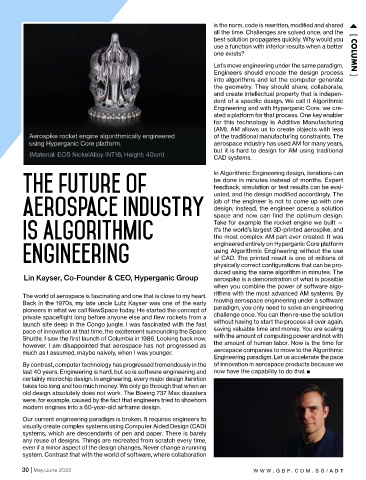

Aerospike rocket engine algorithmically engineered of the traditional manufacturing constraints. The

using Hyperganic Core platform. aerospace industry has used AM for many years,

but it is hard to design for AM using traditional

(Material: EOS NickelAlloy IN718; Height: 40cm) CAD systems.

The future of In Algorithmic Engineering design, iterations can

be done in minutes instead of months. Expert

feedback, simulation or test results can be eval-

aerospace industry uated, and the design modified accordingly. The

job of the engineer is not to come up with one

design; instead, the engineer opens a solution

space and now can find the optimum design.

is Algorithmic Take for example the rocket engine we built —

it’s the world’s largest 3D-printed aerospike, and

the most complex AM part ever created. It was

Engineering engineered entirely on Hyperganic Core platform

using Algorithmic Engineering without the use

of CAD. The printed result is one of millions of

physically correct configurations that can be pro-

duced using the same algorithm in minutes. The

Lin Kayser, Co-Founder & CEO, Hyperganic Group aerospike is a demonstration of what is possible

when you combine the power of software algo-

The world of aerospace is fascinating and one that is close to my heart. rithms with the most advanced AM systems. By

Back in the 1970s, my late uncle Lutz Kayser was one of the early moving aerospace engineering under a software

pioneers in what we call NewSpace today. He started the concept of paradigm, you only need to solve an engineering

private spaceflight long before anyone else and flew rockets from a challenge once. You can then re-use the solution

launch site deep in the Congo jungle. I was fascinated with the fast without having to start the process all over again,

pace of innovation at that time, the excitement surrounding the Space saving valuable time and money. You are scaling

Shuttle. I saw the first launch of Columbia in 1986. Looking back now, with the amount of computing power and not with

however, I am disappointed that aerospace has not progressed as the amount of human labor. Now is the time for

much as I assumed, maybe naively, when I was younger. aerospace companies to move to the Algorithmic

Engineering paradigm. Let us accelerate the pace

By contrast, computer technology has progressed tremendously in the of innovation in aerospace products because we

last 40 years. Engineering is hard, but so is software engineering and now have the capability to do that.

certainly microchip design. In engineering, every major design iteration

takes too long and too much money. We only go through that when an

old design absolutely does not work. The Boeing 737 Max disasters

were, for example, caused by the fact that engineers tried to shoehorn

modern engines into a 60-year-old airframe design.

Our current engineering paradigm is broken. It requires engineers to

visually create complex systems using Computer Aided Design (CAD)

systems, which are descendants of pen and paper. There is barely

any reuse of designs. Things are recreated from scratch every time,

even if a minor aspect of the design changes. Never change a running

system. Contrast that with the world of software, where collaboration

30 | May/June 2022 WWW .GBP .COM.SG/ ADT